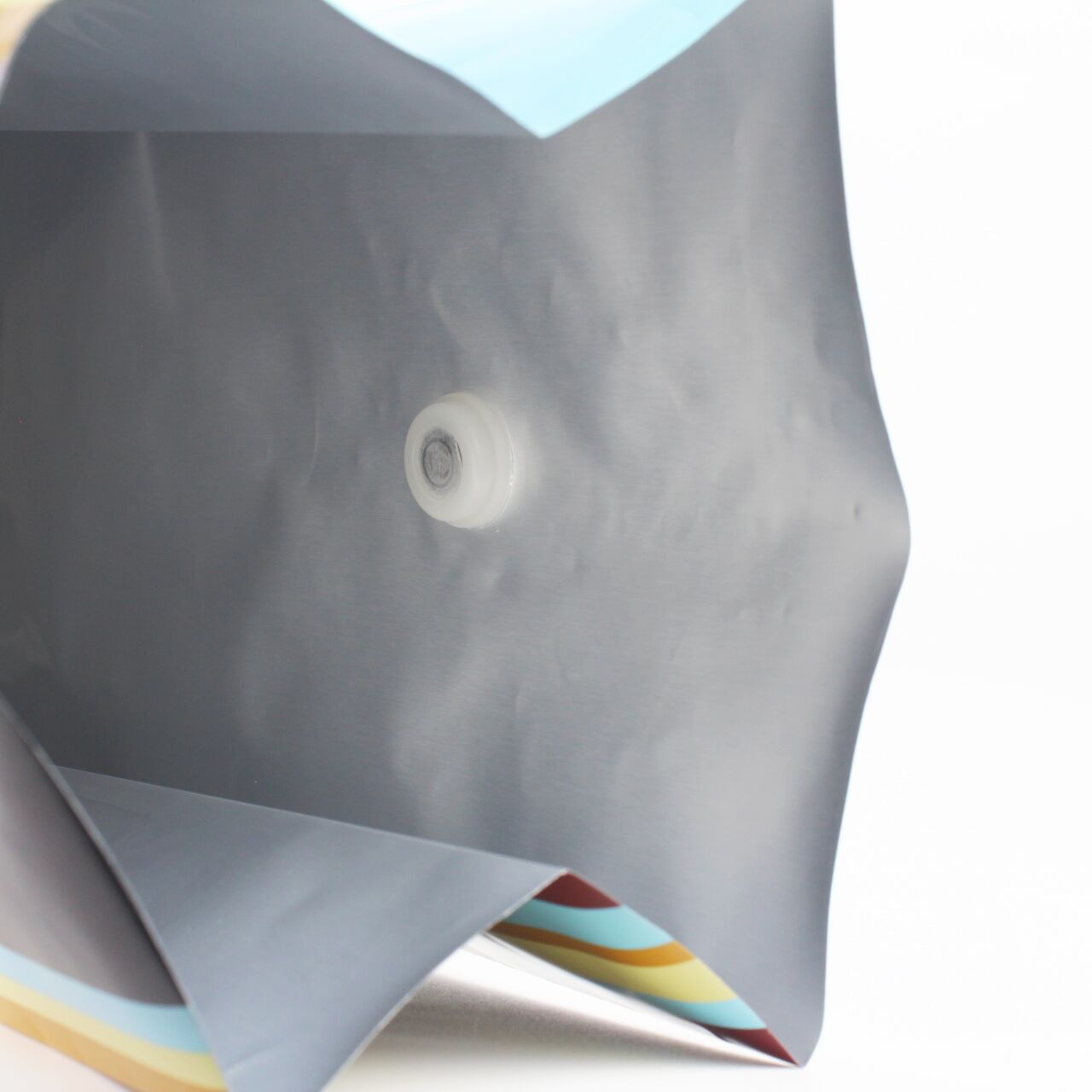

Designed to meet the diverse needs of liquid products, our spout pouches

dispense easily and look great. With a wide range of customization options such

as materials, finishes, sizes and shapes, we ensure our spout pouches meet your

specific packaging requirements. This versatile pouch format is suitable for a

variety of applications, from packaging frozen cocktails and pet shampoo to

beauty scrubs, cleaning products and play sand.

Customizable design: Add your logo, branding, and product information to create a unique look.

Spout Pouches Custom

Custom spouted pouches are a popular choice for packaging liquids such as beverages, as well as hygiene, personal and home care products. They feature a resealable spout for easy, mess-free pouring. Using strong, high-barrier materials also helps extend the shelf life of the contained products.

About us

Products information

-

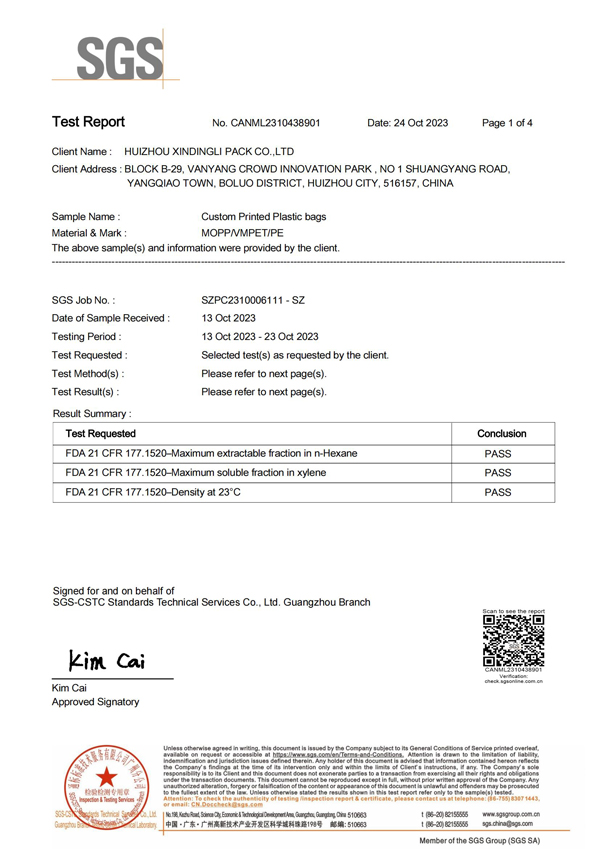

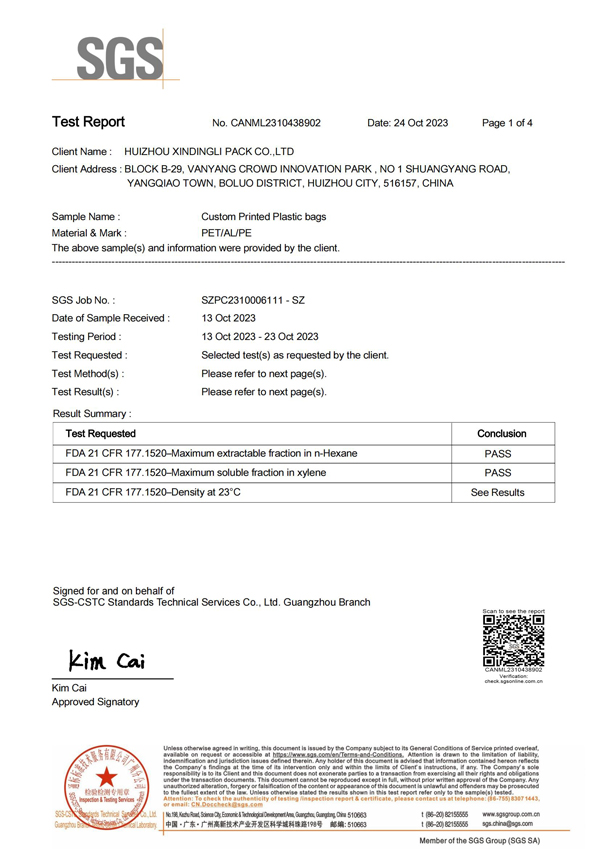

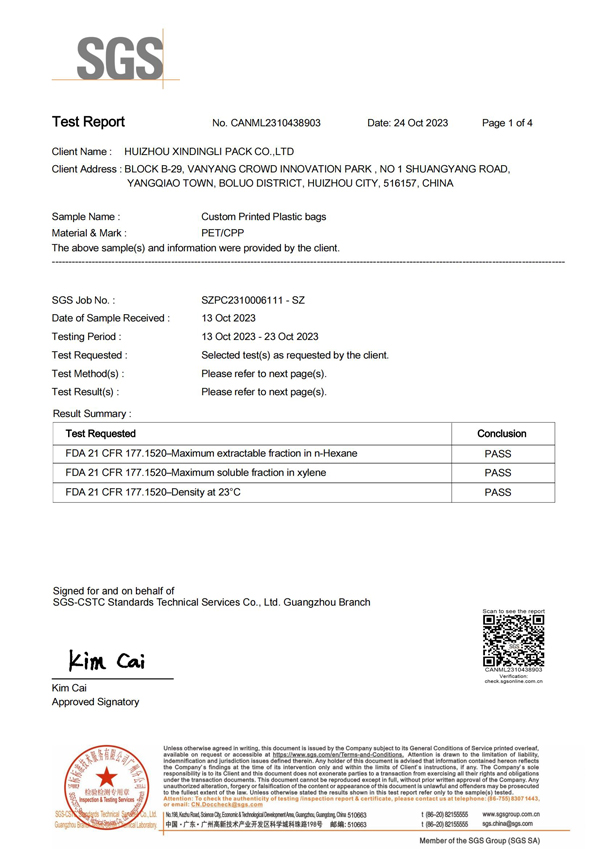

Material

PET/NY/PEfood grade material, non-toxic

-

Printing

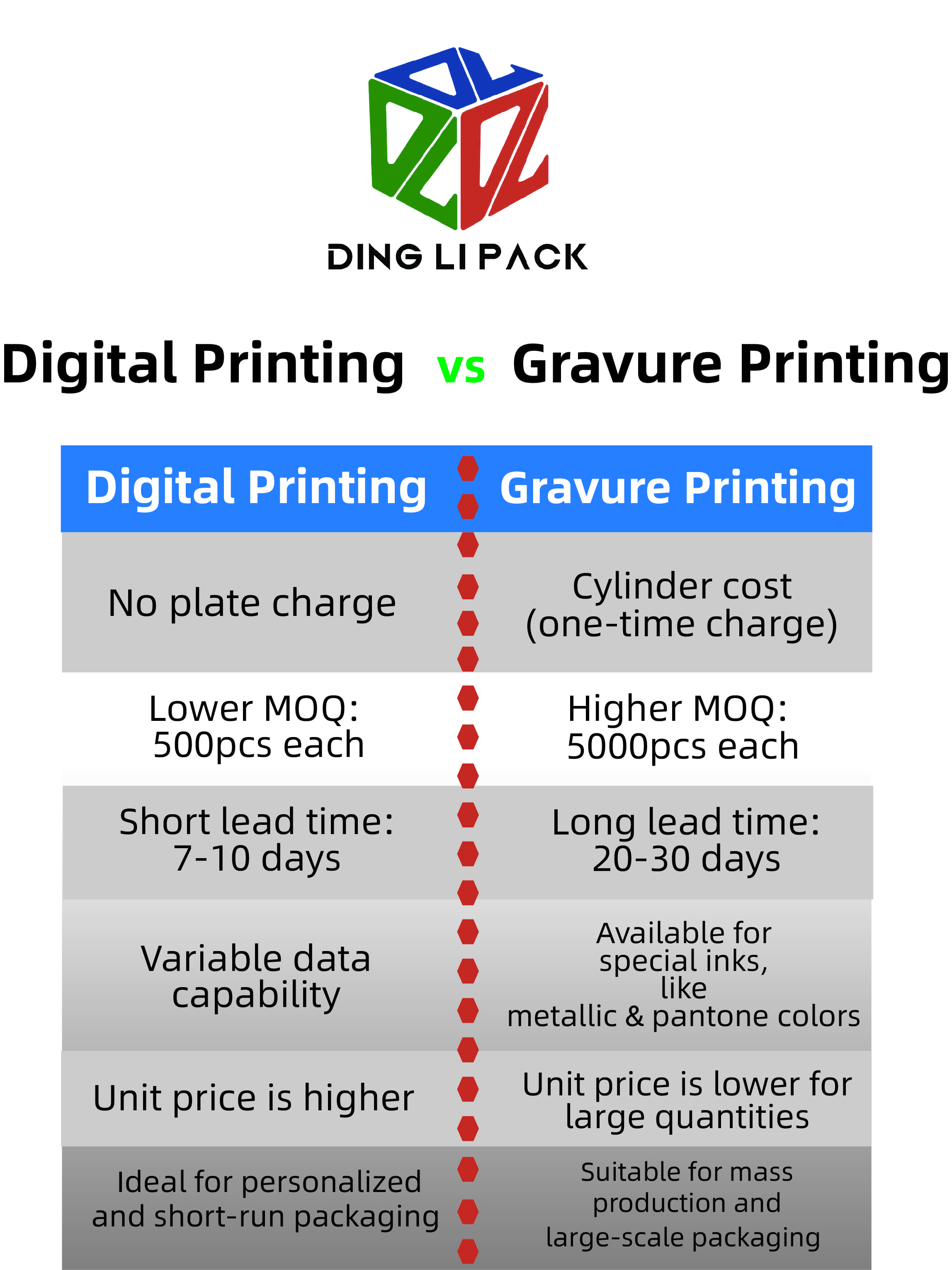

Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors

-

Finishes

matte finish, gloss finish, holographic finish

-

Function

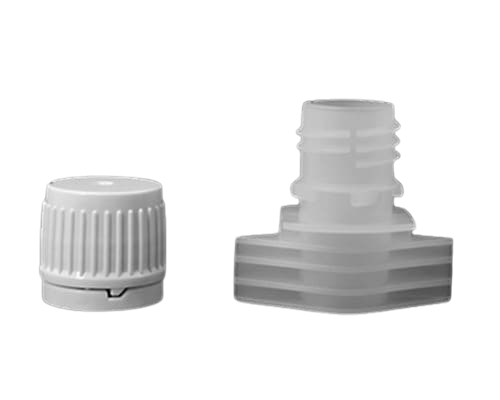

Punch Hole, Handle, Spout(All Diameter Available)

-

Sizes

Variety of sizes to fit any product

-

Order

Order as few as 500 or as many as 10,00000

Factory Introduction

Premium Chinese Spout Pouch Manufacturer

Since 2011, TOP PACK has been committed to perfecting the production of spout pouches. As the large-scale manufacturer of self-standing spout pouches in Guangdong Province, China, we have established expertise and reliability in this field.

Contact usOur bags are carefully crafted from high-quality materials to ensure long-lasting durability and optimal product protection.

You can choose from a variety of options, such as:

Polyethylene (PE): flexibility, toughness, and ability to be heat sealed, making it ideal for forming the body of the pouch.

Polyethylene terephthalate (PET): provides excellent barrier properties against gases like oxygen, which can extend the shelf life

Interested?

Let us know more about your project.

Spout Pouch FAQ

We specialize in creating custom bags with unique features and benefits based on your specific product packaging needs. Our team is dedicated to providing support and guidance throughout the entire process to make your process as easy as possible. If you can't find the bag you need, please let us know as we can create a custom replacement to meet your packaging requirements.

What is the MOQ for Spout pouch?

The regular minimum order quantity for traditional stand-up spout pouches is 10,000 pieces per SKU (same size, same printing). However, for new projects or startups, we are happy to offer reduced MOQ of 1000 pieces or more as a special promotion.

Is Spout pouch available with custom printing?

Yes, customized printing is one of the most important features for all flexible packaging, not only for spout pouches.

Can the spout be welded by the pouch corner? Or only by the middle-top?

It will be the choices of the clients. The spout can be put on middle top, and as well as the left or right top corners.

What are the key factors to consider when choosing Spout pouches?

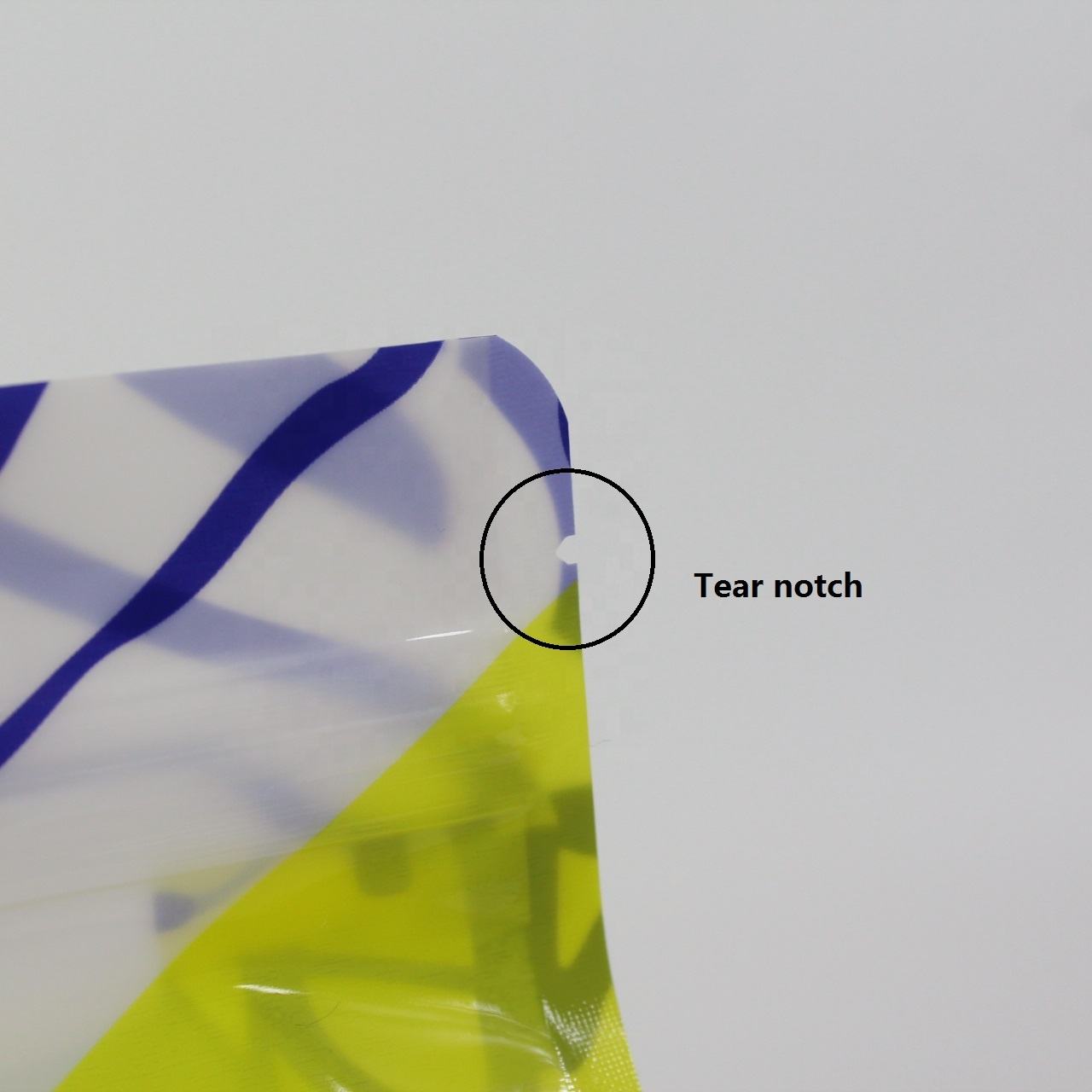

When selecting packaging bags for light- or moisture-sensitive products, it is important to consider factors such as shelf life, barrier protection and resistance to external factors. Choosing bags with the right barrier properties is critical to maintaining product quality. Additionally, it’s critical to consider the end-user experience and how the bag design enhances usability and convenience.

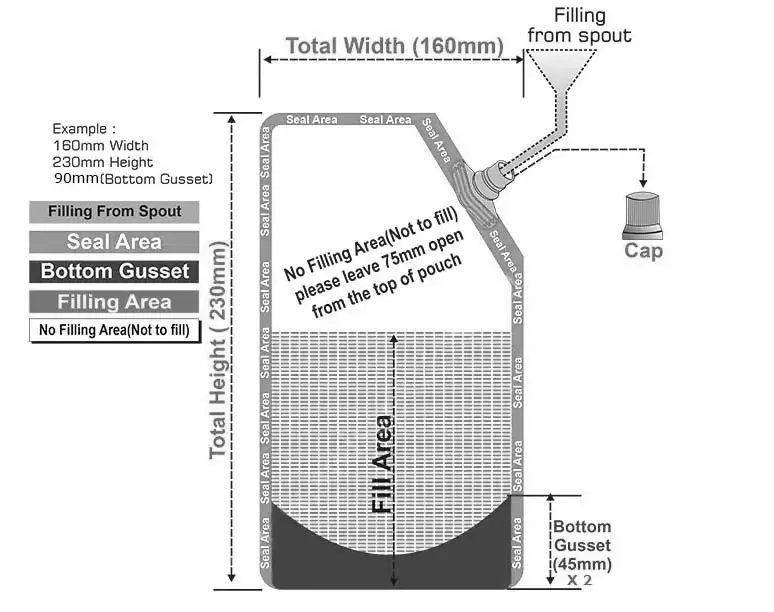

What is the maximum volume or weight your products can hold?

Different packaging materials and formats have unique considerations. The Customisation section shows the dimension allowances for each product and range of film thicknesses in microns (µ); these two specifications determine volume and weight limits.

Can I get custom sizes?

Yes, if your order for custom packaging meets the MOQ for your product we can customise the size and print.

What industries are suited to a spout pouch?

China Top Shaped Pouch Manufacturer & Supplier

TOP PACK is a famous manufacturer of customized special-shaped bags in China and has its own factory. We have a strong reputation for providing high-quality die-cut bag and custom printed bag solutions, dedicated to meeting our customers' unique custom needs at competitive factory prices.

THE COMPREHENSIVE GUIDE TO SPOUT POUCH PACKAGING

Welcome to our comprehensive guide on the world of stand-up pouch packaging! As a leading packaging production company, we're excited to share our expertise and insights on this innovative and versatile packaging solution. Whether you're a seasoned professional in the packaging industry or simply curious about the latest trends and technologies, this blog is designed to provide you with all the information you need to make informed decisions about your packaging needs.

Q1:What are Spout Pouches?

In popular terms, it is to add a suction nozzle to the stand up bag. Among them, the bag part is no different from the ordinary stand-up pouch, the bottom has a layer of film to support standing, and the suction nozzle part is a general bottle mouth with a straw. The two parts are closely combined to form a new packaging method - a suction mouth bag. Because it is flexible packaging, this packaging is easier to smoke and control, and it is not easy to shake after sealing, which is a very ideal packaging method.

Q2:How to choose different Materials?

Q3:Can the Stand Up Spout Pouches for sauce be Cooked Directly?

Q4:What are the Barrier Material's Structure?

The spout pouch's material composition is not always apparent, as it may consist of various materials to achieve high barrier properties.

Q5:Can Spout Pouches be used for products with varying viscosities?

Q6:What are the typical sizes and capacities of Spout Pouches?

Q7:The difference between metal and non-metal structure

In comparing metal and non-metal composite structures for spout pouches, several key differences emerge. Metal composites offer superior barrier protection and extend product shelf life due to their opacity. They also provide a shinier appearance and superior printing and graphic effects. However, metal composites lack the recyclability of non-metal composites, which align with the future direction of sustainable development by utilizing recyclable materials.

Q8:How To make customized spout pouch?

Q9:What are the printing options?

Q10:Any Available prints and finishes of spout pouch?

Spout pouches offer a range of print and finish options, including:

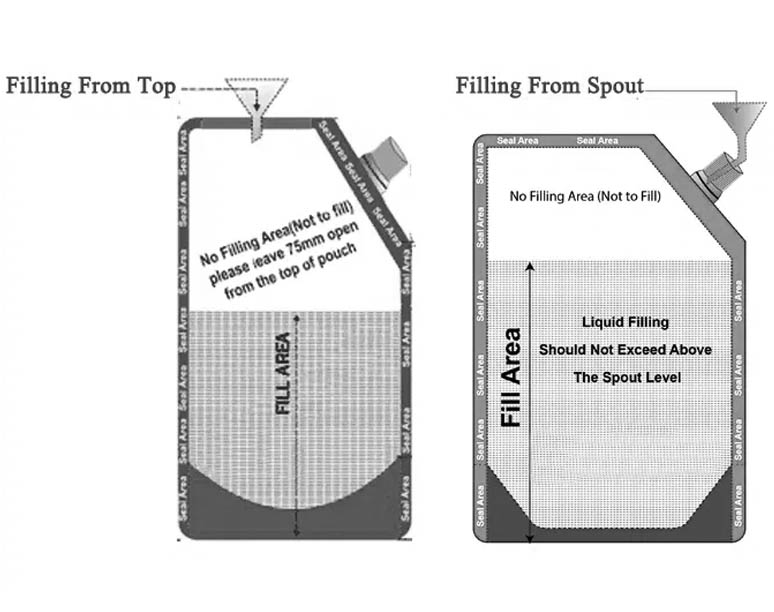

Q11:How to Fill Spouted Pouchs with Liquid Products?