Custom-Printed Stand up Pouches

Here at XINDINGLI PACK, we create the best custom-made stand-up pouches for your unique products right here in China. Whether you need pouches in large or small sizes, with different print finishes, or any custom feature you can imagine, XINDINGLI PACK can make it happen.

In recent years, stand up bags have become a hot product in the new century because of their practical use, beauty and low cost. Like other packaging types, it acts as a barrier between the product and its environment, but the standing bag is made of a slightly stiffer material that allows it to stand on its own, making it easier for consumers to store and use. The company is a leading manufacturer and innovator in this field, producing a large number of products for various industries such as cosmetics, food, agriculture, pharmaceutical, protein powder packaging, medical, coffee and tea packaging, gourmet packaging, and more.

Whether you have your own design or need our expert creatives to lend a helping hand, XINDINGLI PACK has you covered. You can package any product you need into custom printed stand up pouch, and we've got a perfect-fitting pouch for any quantity. We can make sure you get exactly what you need.

Contact us

-

1

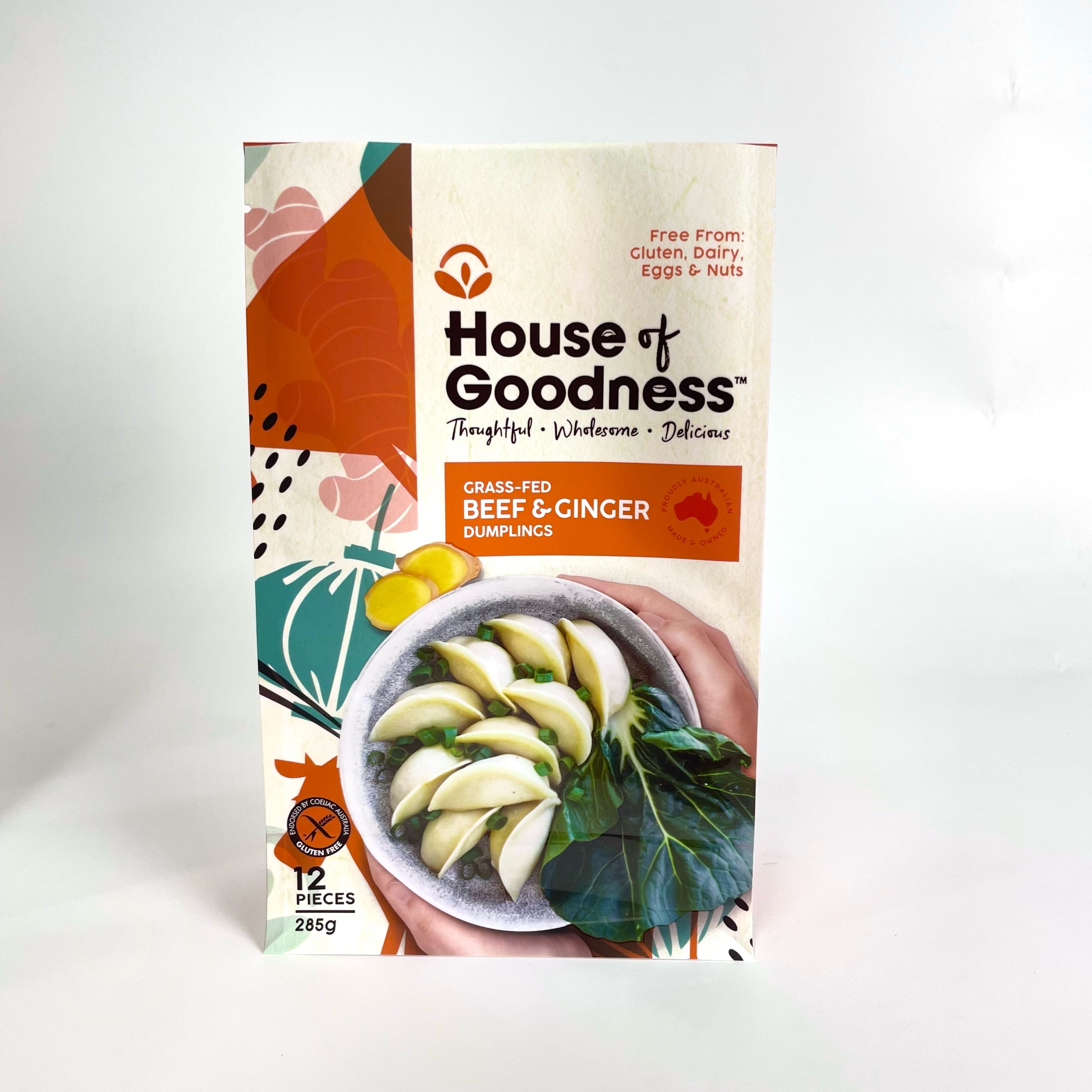

Create artwork that represents your brand.

Are you into a minimalist design? Or do you like to add a pop of color to your packaging? Regardless of your design preference, your artwork should stay on brand so that customers can easily remember it. Use colors and typography that best reflect your brand personality.

-

2

Make certain areas of your design pop out with white ink.

White ink can make your design look more vibrant. It’s useful when you want specific areas of your artwork to appear white. Without it, the design will have the same color as the film underneath it. White ink is available on clear and metallized Film.

-

3

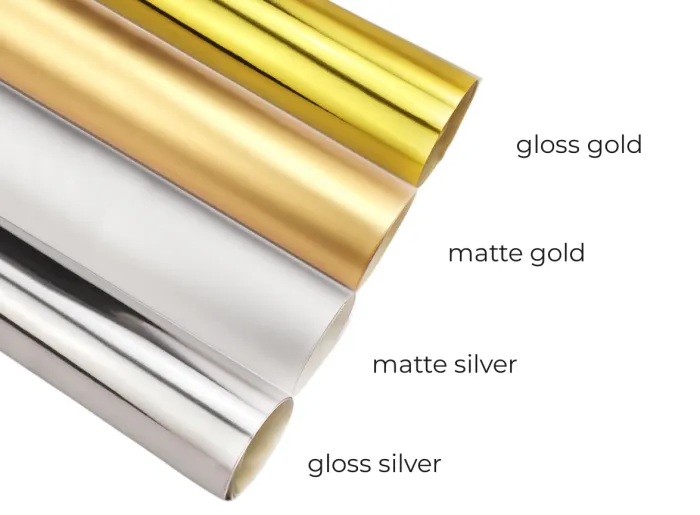

Choose the coating for your pouches.

Matte coating has an elegant finish. It has a muted appearance, which is best suited for brands that want to look classy and polished. Gloss coating has a shiny appearance that makes the color look more vibrant. Bright colors combined with the shiny finish are perfect for brands that want to appear bold and fun.

-

4

Add helpful product information.

Make it easier for customers to decide that your product is best by adding useful product information. Nutritional information, directions on how to use, ingredients, and best by dates are handy when customers are confronted with similar products.

-

Trust in Dependable Products

Trust in Dependable Products Enjoy Cost-Effective Solutions

Enjoy Cost-Effective Solutions Deliver Premium-Quality Goods

Deliver Premium-Quality Goods -

Recover Lost Revenues Innovate Your Way to Success

Innovate Your Way to Success

Avoid Common Traps

-

1.We connect you directly with the factory, cutting out middlemen.

1.We connect you directly with the factory, cutting out middlemen. -

2.We value open communication and trustworthiness in all our interactions with you.

2.We value open communication and trustworthiness in all our interactions with you. -

3.We never sacrifice product excellence for cost savings, ensuring the highest quality for your investment.

3.We never sacrifice product excellence for cost savings, ensuring the highest quality for your investment. -

4.We stand behind every product with a 100% satisfaction guarantee.

4.We stand behind every product with a 100% satisfaction guarantee. -

5.Our team is on-site at the factory, providing supervision for quality assurance at every step.

5.Our team is on-site at the factory, providing supervision for quality assurance at every step.

-

6.We ensure smooth and reliable delivery through our dedicated logistics partners.

6.We ensure smooth and reliable delivery through our dedicated logistics partners. -

7.We prioritize the well-being of our employees and partners

7.We prioritize the well-being of our employees and partners -

8.We provide customization options to help you create packaging that fits your brand identity.

8.We provide customization options to help you create packaging that fits your brand identity. -

9.Our dedicated team provides free design expertise to bring your vision to life

9.Our dedicated team provides free design expertise to bring your vision to life -

10.We're committed to using eco-friendly materials and reducing waste to protect our planet.

10.We're committed to using eco-friendly materials and reducing waste to protect our planet.

How big are the hang holes? Are they available on all stand-up pouch sizes?

The Euro hole is 0.39" x 0.98", while the round hole is 0.31" in diameter. On all pouch sizes but 1, both of our hole options are available. For our smallest pouch (3.25" x 4.75" x 2"), only the round hole is available.

Are there plate charges for printing stand-up pouches?

Can I print on both sides?

Yes, you can customize on both sides! Plus, you can have multiple designs in one order.

Are your stand-up pouches safe for food items?

How big are the hang holes? Are they available on all stand-up pouch sizes?

What are the pouch dimensions?

What is your turnaround time on stand up pouches?

Order Your Stand-Up Pouch Sample Pack !

If you're uncertain about testing your design with our products, don't worry. Instead, you can order a stand-up pouch sample pack, which includes every product type we sell. There are glossy stand-up pouches, flat bottom bags, spout pouchs,shaped pouchs from XINDINGLI PACK, and more..

Unleash Your Product's Potential with Custom Stand-Up Pouches!

Tailored Solutions for Unique Formulas

Advanced Prototyping and Testing

Award-Winning Packaging Expertise

Consumer-Centric Designs That Stand Out

Partner with us to elevate your brand and captivate your customers.

Get productTHE COMPREHENSIVE GUIDE TO Stand up POUCH PACKAGING

Welcome to our comprehensive guide on the world of stand-up pouch packaging! As a leading packaging production company, we're excited to share our expertise and insights on this innovative and versatile packaging solution. Whether you're a seasoned professional in the packaging industry or simply curious about the latest trends and technologies, this blog is designed to provide you with all the information you need to make informed decisions about your packaging needs.

Q1:What are stand up pouches?

Stand-up pouches,also known as Doypacks,are a type of flexible packaging that has gained popularity due to their convenience,versatility,and ability to stand upright on store shelves.These pouches are made from a combination of plastic films,often laminated together to provide strength,barrier properties,and printability.

Q2:Why stand up pouches can replace rigid packaging?

They are cost-effective,with production costs being up to 50% lower than rigid containers. Their lightweight nature reduces shipping costs by up to 4-5 times compared to metal cans.

Q3:The benefits of the stand up pouch to the end consumer

Q4:More features of the stand up pouch

Material Efficiency:They are made from flexible materials,which require less material compared to rigid packaging,resulting in reduced waste and lower production

Q5:The barrier material's structure of the stand up pouch

Q6:The process of manufacturing stand up pouches

Q7:How to evaluate the quality of the stand up pouch?

Material Quality: Ensure the material is strong, food-grade, and suitable for the intended use.